Vertical injection molding machines are specialized systems designed for precision molding of plastic components. These machines inject molten plastic right into a mildew to create complex, high-quality components. They function as a vertical clamping unit and an injection unit that operates vertically, making them perfect for insert molding, in which additives like metal elements or digital connectors are located into the mold earlier than injection.

This configuration gives high-quality component alignment and reduces the footprint, taking into account smooth automation and integration into production strains vertical injection molding machines are generally utilized in industries consisting of automotive, electronics, clinical devices, and patron goods, providing reliable performance, high efficiency, and steady product quality.

Challenges Faced When Using Vertical Injection Molding Machines

Vertical injection molding machines are crucial in the production industry, mainly for generating precision components with inserts and over-molding applications. Despite their specialized capabilities, those machines pose several challenges which can impact manufacturing performance and product quality. Here are some of the common demanding situations faced whilst using vertical injection molding machines:

Setup and Alignment Complexity

Vertical injection molding machines require precise setup and alignment, which may be extra complex in comparison to their horizontal opposite numbers. The vertical orientation needs accurate positioning of the mold and inserts to ensure consistent part exceptional. Misalignment can lead to defects consisting of flash, quick pictures, or unsuitable filling of the mildew hollow space. This complexity necessitates skilled operators and can cause longer setup times, increasing downtime and lowering standard productivity.

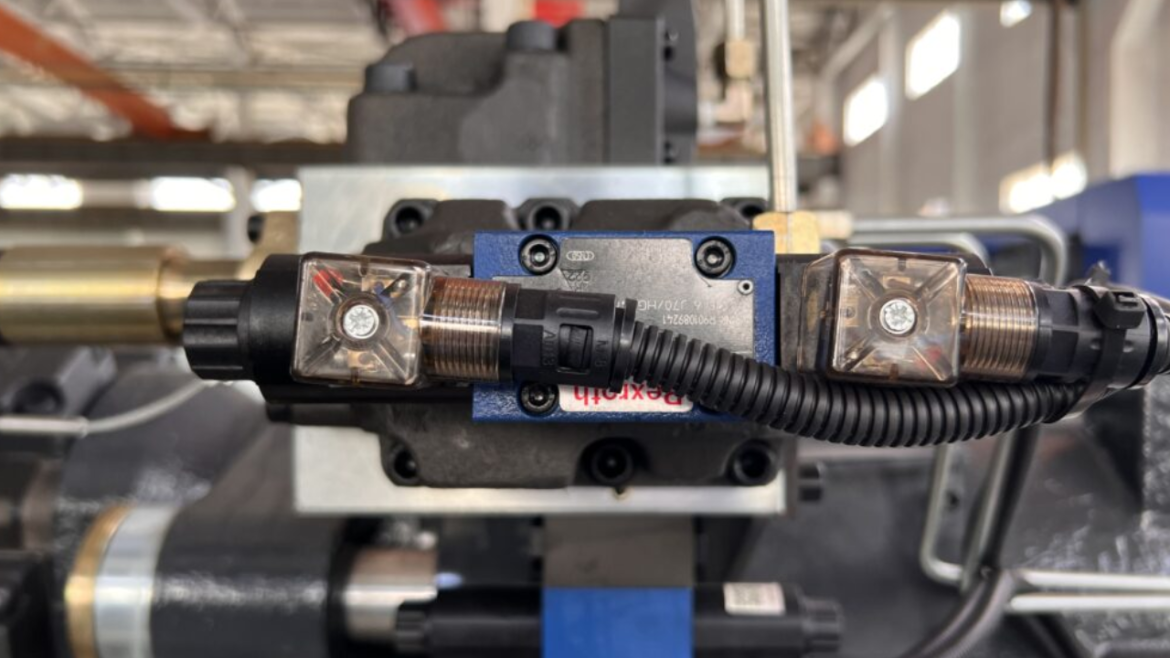

Maintenance and Wear

The vertical configuration places specific stresses on machine components, specifically on the clamping unit and mold. Gravity’s consistent effect means additives like tie bars and manual rods can experience uneven wear, doubtlessly main to mechanical disasters. Regular maintenance is critical to screen and cope with wear and tear, however, this will increase operational costs and require scheduling downtime, which could disrupt production schedules.

Handling and Ergonomics

At the same time as vertical machines are beneficial for insert molding, the manual insertion and elimination of components can pose ergonomic demanding situations. Operators regularly work at better levels or in awkward positions to area inserts or get rid of finished parts, which can cause fatigue and repetitive pressure injuries. Ergonomic considerations are vital to ensure employee safety and efficiency. Implementing computerized structures to deal with inserts can mitigate those issues, though it adds to the initial funding and complexity of the setup.

Cycle Time Efficiency

Achieving optimal cycle instances with vertical injection molding machines may be challenging due to the precise nature of vertical mold opening and closing. The need to manually area inserts or components can slow down the cycle time in comparison to completely automated horizontal structures. Despite automation, the vertical mildew moves can be slower, affecting average manufacturing speed. Producers should stabilize the want for precision and quality with the demands for quicker cycle instances.

Material Flow and Molding Consistency

The vertical configuration affects the material flow in a different way than horizontal machines. Ensuring uniform material distribution and regular first-rate can be tough, particularly for complicated or multi-cavity molds. Variations in material viscosity and float can lead to issues like choppy element dimensions, sink marks, or inner stresses. Constant manner tracking and manipulation are essential to maintain pleasant, often requiring superior sensors and software, which adds to the complexity and cost.

Space Utilization and Layout

Vertical injection molding machines normally have a larger footprint in terms of height, which could pose demanding situations in manufacturing facility format and space utilization. Facilities want to deal with the peak and extra protection clearances, which would possibly restrict the variety of machines that may be installed or require changes to the present layout. Efficient space utilization strategies are vital to maximize manufacturing capacity without compromising safety or workflow.

Cost Considerations

The initial cost for vertical injection molding machines can be better than for horizontal machines, especially whilst considering the additional costs for automation and advanced manipulate structures required to cope with some of the aforementioned challenges. Moreover, the operational costs, such as maintenance and energy consumption, can be significant. Producers want to carry out a thorough cost-advantage evaluation to justify the investment and ensure long-term viability.

Conclusion

Vertical injection molding machines, while beneficial for inserting and over-molding, present demanding situations that include complicated setup, renovation, ergonomic problems, and higher costs. Addressing these requires superior generation, regular maintenance, efficient layout planning, and professional operators. Expertise and mitigating these demanding situations can optimize a machine’s overall performance, making sure of high manufacturing and operational performance.