No other company can offer that amount of certainty to their customers. Why not take the risk out of getting custom stickers? Customized JJC sticker has been providing one stop shop for branding your car stickers, laptop stickers, even your phone cases. The online store is very user-friendly and promoting the company values of hard work, service, integrity and innovation. Go now and discover what this picture-perfect company has to offer:

Faultless raw material:

With the widest selection of sticker materials, the stickers will last you through sweat and multiple layers. Likewise they have three different types of vinyl material—vinyl foam soft-touch, hard or durable vinyl—to meet all your needs during workouts or for extended outdoor use. With vibrant colors, high scratch resistance and UV light protection, you’ll be sure to find a perfect match with one of these materials. JJC Products, established by Jjicsticker, is an online store that offers affordable and high-quality vinyl stickers. They provide a wide variety of imprinted vinyl’s in different colors to meet the needs of all customers.

JJC Company has fantastic specials with clearances for nonstop shopping. Do you need great quality stickers made with precision? Contact JJC Company to see how their experienced professional can help make your dreams come true. Waterproof and dust-free they will make your products shine every day…any day.

Experienced designers:

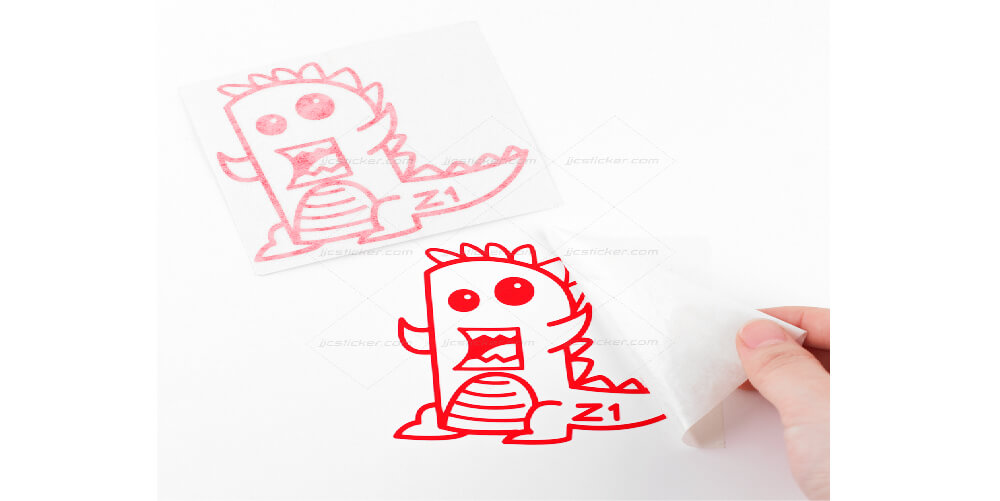

Sticker can be any dimension with a range of size options. Stickers at the JJC shop are available in white or clear polyester and you can choose to print on them or apply your logo as an adhesive sticker. Custom logos and artwork such as business cards, product packaging, magazine ads, etc., can also be printed on stickers. The online tool helps you create the perfect design for personalized stickers by offering customization across dimensions and qualities– all at once!

Established customized JJC stickers:

JJC sticker offers a wide range of custom holographic stickers able to fulfill any requirement from the customer. They grant competitive prices and speedy delivery due to patented printing technology, ensuring a great customer experience for all. JJC manufacturing is a years old specialized custom hologram sticker manufacturer producing more than 30 kinds of stickers.

Putting on new summer outfit? Craving fresh air? Try turning your car into an open window with plastic cling copies along the windows and doors. Their strong and water-resistant finish will make you proud.

Reliable and versatile stickers:

JJ Sticker specializes in producing custom holographic stickers, creating a well-rounded product. At the unit cost rate per sticker for any design and quantity, JJ Sticker is an economical choice for individuals at a multitude of budgets. Whether you’re a teacher needing 30 bumper stickers or just one business looking for fun promotional material to hand out at your next event, JJSticker has got you covered.

When you’re running a business, one of the key components is branding. If your company doesn’t have a noticeable logo or color scheme, then customers will have just as much trouble finding you from other companies. So what are you waiting for?