Modern society depends on custom apparel manufacturing to produce distinctive high-quality clothing that distinguishes itself from standard products. Fashion creation starts from artistic collaboration with innovative approaches and detailed precision which results in lasting fashion pieces. This article examines the complete process of high quality apparel manufacturing that starts with design ideas and ends with finished products.

The Concept and Design Process

A high-quality custom garment starts with a well-defined vision. Manufacturers and designers maintain continuous collaboration to develop fashion concepts into actual clothing items. The initial phase requires extensive dialogue between manufacturers and designers to determine the apparel’s purpose and target audience, and preferred design elements. The design process includes both pattern sketching and material selection, and exact decisions about garment structure and fit, and finishing details. The objective remains to create products that appeal to users yet preserve superior quality standards.

Selecting the Right Materials

Every exceptional piece of custom apparel depends on the selection of its materials. Premium fabrics serve to improve both the visual appeal and longevity and comfort of the final product. Manufacturers who focus on custom apparel gain access to high-quality textiles that come from international sources. The selection of appropriate materials, including cotton and silk, and performance fabrics, stands as a vital step to develop fashion that leaves a lasting impact. Manufacturers select materials that meet three essential criteria: durability and sustainability alongside perfect functionality for each garment to achieve both practicality and visual appeal.

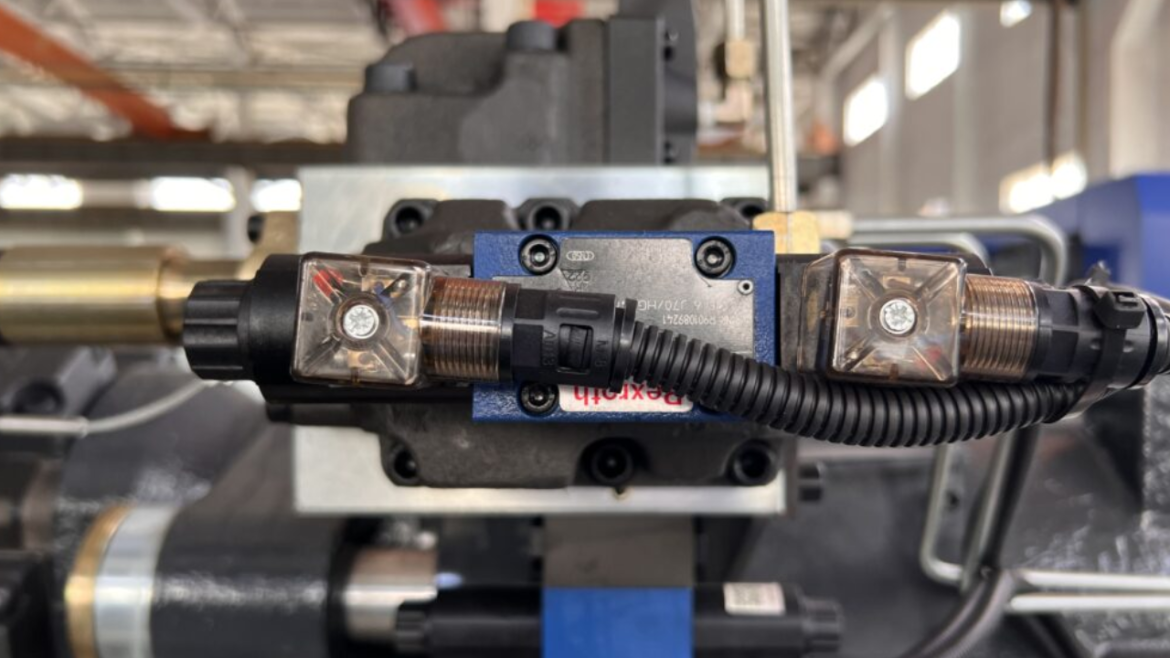

The Manufacturing Process

The manufacturing process starts after designers finalize their choices regarding design and materials. The manufacturing process begins after designers finalize their choices regarding materials and design specifications. The success of this phase depends heavily on skilled workers who pay close attention to details. The fabric gets cut by experienced workers who ensure every piece follows the precise design specifications. Manufacturers focus on creating a flawless fit combined with superior finish quality and durable construction. The manufacturing team works diligently to bring out the original design while displaying the unique features that distinguish custom-made garments from standard commercial fashion products.

Quality Control and Refinement

High-quality custom apparel requires strict adherence to quality control standards because any compromise in this area leads to unacceptable results. Multiple inspections happen on the garment during its entire manufacturing journey. The inspection process evaluates both the precision of stitching and the condition of the fabric materials. The garment reaches its status as fashion art through extensive quality checks, which transform it from basic clothing.

The Final Product

The garment moves forward to delivery status after completing all necessary quality examinations. The finished garment represents more than clothing because it stands as a powerful statement. Custom apparel of superior quality serves as a tool to create emotional responses while boosting self-assurance and establishing individuality in the wearer.

Conclusion

The manufacturing process for high-quality custom apparel combines multiple complex steps. These include design through material selection and ending with craftsmanship and quality control. Fashion impact goes beyond clothing production because it involves crafting distinctive products that demonstrate superior quality alongside meticulous craftsmanship. Fashion creation goes beyond manufacturing clothes because it involves making pieces that showcase individuality and superior quality craftsmanship. Custom apparel manufacturing stands as an essential component for achieving exceptional fashion in the evolving fashion industry.