Laser rust cleaning is an efficient procedure used to clean metal parts. It is a secure and faster way of removing rust from any metal type using a fiber rust cleaning laser machinery without destroying the material beneath. Laser rust cleaning is ideal for chemical and manual cleaning techniques since rust is entirely removed without changing the metal’s quality.

Laser cleaning applications

1. Surface preparation treatment and removal of rust in steel fabrication

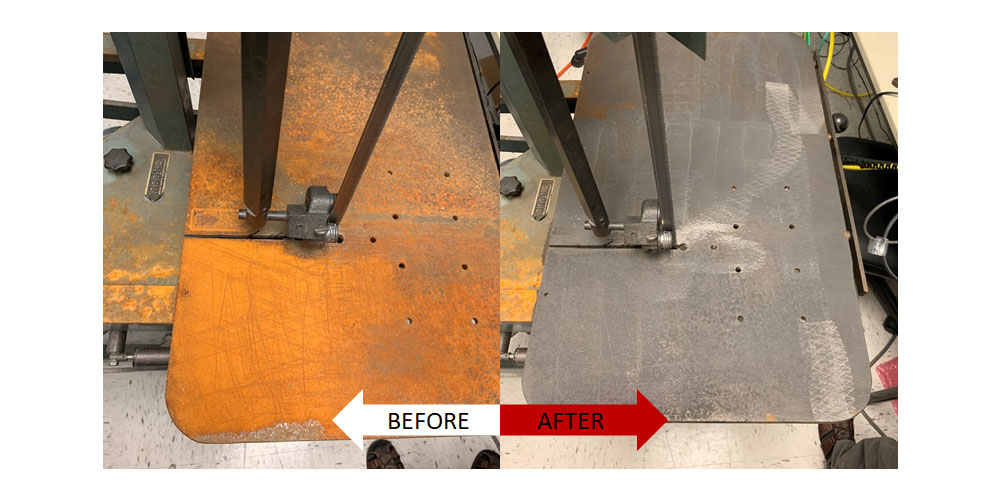

Laser cleaning is an efficient technique for discarding scale and rust from metal surfaces. Rust and scale are impurities that form on the surface of metals due to artificial or natural procedures. When you expose metals to moisture, they react, forming ferrous oxides that turn into rust. Rust reduces the quality and purity of the metal, which makes it unfit for use.

Scales are formed on metal surfaces due to heat treatment processes, and the result discolors metal surfaces stopping succeeding operations. These unwanted surface materials are removed by repeatedly passing a top peak power laser beam on the affected layer. The rust quickly absorbs the laser beam’s energy leading to high-temperature levels, and the rust melts and turns into vapor.

2. Surface profiling

Laser cleaning is used to remove all impurities such as grease, oil, and scale from metal surfaces and parts as you prepare to apply a protective coating. For preceding processes, the wires, profiles, and bars must be clean.

3. Removal of coating material from battery foils (Anode cleaning)

The removal of all surface impurities from the anode is necessary before being used for various aluminum smelting processes. Quality is essential for this procedure since the coatings should be entirely discarded without harming the thin foils. You can use laser cleaning to clean anodes through:

- Removing residue from carbon butts

- Removing dirt from cathode bars

- Removing impurities and stain from stub rods and thimbles

4. Adhesive bonding preparation for metals

The metallic surfaces must be joined to be prepared before welding and additional joining requirements.

You can use laser cleaning to prepare metal surfaces before joining them to produce a splendid bond of strength and quality. The result should be durability and corrosion resistance. Laser cleaning discards oxides and other impurities that lower the force of adhesive bonds.

5. Pre-welding treatment and brazing

The removal of rust through laser is a faster way to enhance the fitness of welded parts. Laser cleaning through welding will also help you remove lubricants and other impurities from aluminum and metals’ surface in getting ready for better welds.

Laser cleaning performs the following in pretreatment for brazing and welding:

- To removing hydrates, oxide layers, and shop-primer carefully

- De-oiling and de-greasing for greater tensile strength

6. Pre-coating treatment

Fiber lasers are used to remove a stratum of coating in a specific area. It is done on all surface types to de-coat and discards paint in the aerospace and automotive industries. You can use lasers to remove paint for easy interaction electromagnetically partially.

7. Selective paint removal

Laser cleaning can remove weathered paint coatings in the aerospace and automobile industries before applying new paint.

Final Thoughts

Rust cleaning laser is useful in automotive and aerospace industries, medical technology, and mechanical engineering industrial services.