A lot of people are not sure what flexo printing is about. Flexography is a printing technology that utilizes in-line rotary features. Thus, you can print different things on paper, metallic film, plastic, and cellophane. The good thing about Flexographic Printing Machines is that they provide the ability to print different lengths, use different inks, and much more.

Flexographic printing is based on rubber stamp printing that was common in the 1900s. The FDA found out that the inks utilized in the process were not safe, a few changes were necessary. For instance, the process was improved and new inks were used. In the past, flexo printing was associated with food packaging. However, with technological advancements, this technology is now used in other applications. It is estimated that about 70% of the food packaging industry uses this technology.

Flexo Printing Process

1. Pre-Press Process

This is an important process when it comes to flexo printing. That is because the process is high speed. As a result, errors in plate making can result in wastage of minerals and ink. There is a need to ensure the ink used can print neatly on the substrate.

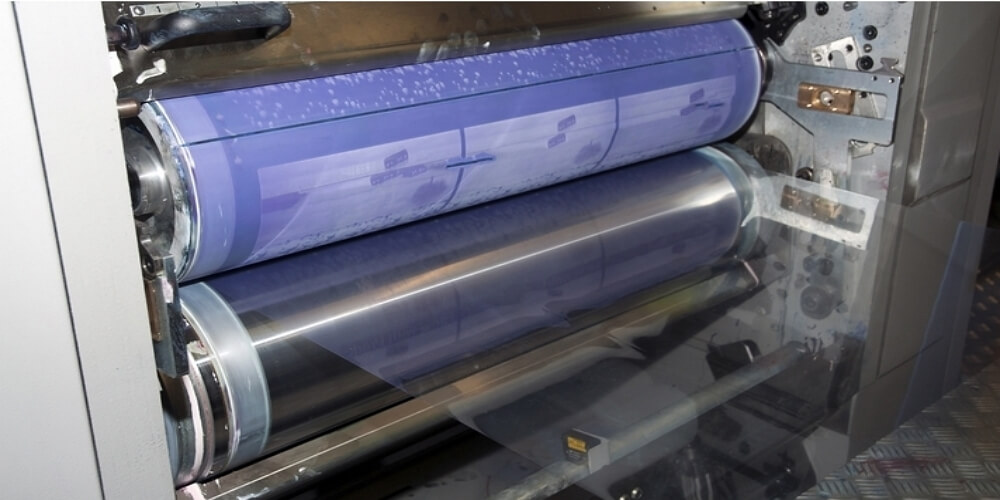

2. Printing Process

You should note that each flexographic printing press has different printing stations, based on the number of colors required. At each station, the material passes through different rotary plates. Rollers used in the process can be classified into fountain rollers, anilox roller, impression cylinder, and plate cylinder.

3. Uses of Flexo Printing

Flexography allows for printing on different substrates such as uncoated or coated paper, plastic film, metal, and other substrates. The fact that various substrates can be printed on, means that flexography can be used to print foils, business forms, envelopes, wallpaper, newspapers, cartons, and food packaging.

How Flexography Compares with Other Printing Techniques

The truth is that flexo printing is a growing segment in the printing sector. In fact, advancements being made in this sector result in the production of quality prints. This is how this technology compares with other printing techniques.

1. Flexo Printing Versus Offset Printing

Offset printing and flexographic printing are widely used in producing different forms of prints. You should note that each method has its pros and cons. When it comes to offset printing, the image is transferred from the plate to the substrate. Ideally, flexo printing is more accurate than offset printing in transferring the image. Thus, you can enjoy high color accuracy and better printing speeds. Also, offset printing is limited to only smooth substrates.

2. Flexo Printing Versus Gravure Printing

When it comes to gravure printing technology, images are transferred into the substrate with the help of a metal place. On the other hand, flexo printing utilizes rubber plates. Thus, flexography is considered to be more diverse and versatile as compared to the gravure printing method.

3. Flexo Printing Versus Digital Printing

Digital printing is a new technology where there is no need for using printing plates. In this case, the ink gets to the substrate with the use of positive and negative charges. Since this is a new technology, it is not widely used but it is growing rapidly.