Every aspect of sheet metal bending is crucial. If one aspect is not followed, then the outcome may not be as desired. The process involved in metal bending requires plasticizing sheet metals in order to change their shape. Therefore, every specification, especially in pattern dimensions, must be followed. Thus, to obtain the proper sheet metal bending, some calculations need to take place. This article aims to offer a guide towards sheet metal bending calculations.

A guide towards sheet metal bending calculations

· K-factor calculation

In sheet metal bending, K refers to a constant used in the calculations of sheet-metal flat length. K-factor is the ratio of material’s neutral line location to its thickness. Generally, it is described by t/T, where T represents thickness and t represents the material’s neutral line location. The critical point to note while calculating the K-factor is that its formula does not consider the forming stress but the neutral line location geometric calculation. The K-factor calculations depend on various aspects. The various aspects include; bending operation type that is air bending, bottoming, coining, and so many others and the type of material used.

· Bend allowance calculation

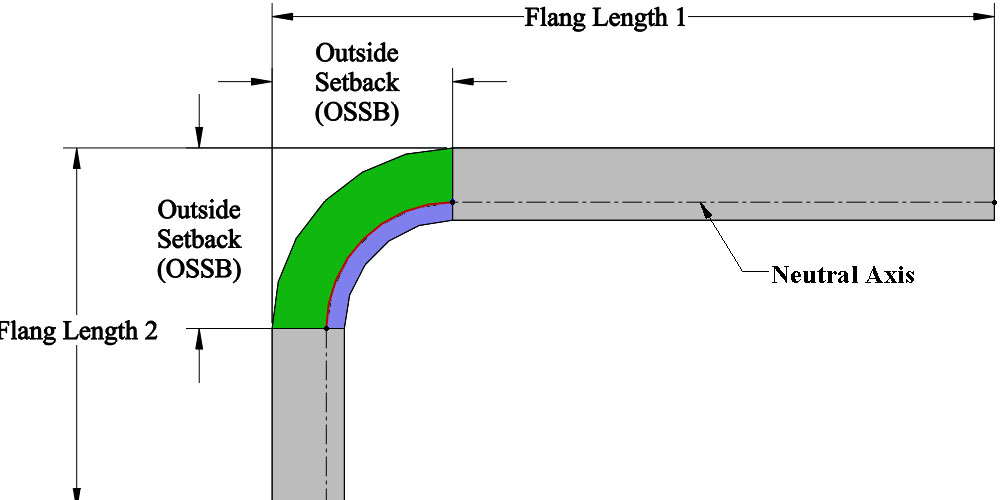

Bend allowance refers to a bend’s arc length that is measured from the material’s neutral axis. Generally, bend allowance can be defined as the material required to include the part’s leg length to obtain the right size for the cut’s flat pattern. Additionally, it calculates the material required to get the sheet-metal flat length. The Bend allowance calculation formula is given by;

Bend allowance can be calculated by; A

A refers to 90 degrees angles, R refers to a radius, K refers to the K factor, and T refers to thickness.

· Bend deduction calculation

Bend deduction is the difference between the total flange length after bending and the beginning flat length. The total flange length sum after bending is complete should be higher than the flat length before bending. The sheet metal bending process ensures that the bend’s inner surface is compressed while the bend’s outer surface is stretched. The bend deduction calculation is given by;

Bend deduction= 2(R+T) tan- bend allowance

Benefits of sheet metal bending

· Cost-effective

Sheet metal bending is cost-effective as it does not allow for material waste during its processes. Thus, the material saved can be bent into more useful shapes.

· Bending accuracy

Sheet metal bending machine ensures that there is bending accuracy. Thus, parts are produced according to one’s exact specifications. Even though the processes require sheet metal deformation, the deformation results are usually accurate.

· Low labor costs

The low labor costs are because the latest sheet metal bending machine allows for automation processes to happen. The automation process ensures that the sheet bending machine requires only one or two operators.

· Efficiency

Sheet metal bending machines are usually high-performing. The high-performing machines guarantee machine efficiency. Thus, it encourages time-saving.

Conclusion

Bend deduction, bend allowance, and K factor are essential factors in sheet metal bending calculations. Any mistake done during the calculations can ensure that the results obtained are not what was expected. Therefore, to get the specified part, it is essential to get correct calculations.