Introduction

No doubt the advent of plastic recycling machines is one of the greatest improvements in the waste management industry. Empty plastic cans previously regarded as useless can now be put to great use after it has been recycled.

If you take a minute to wonder what our world would have looked like if there was nothing like recycling, you would realize that the view wouldn’t be so pleasant.

What is a Recycling Machine?

A recycling machine is a type of Machine used to flux plastic products into granules. These granules can now be used in the manufacture of various other products. Recycling is one of the branches that makes environmental engineering.

Plastics are non-biodegradable materials, the more reason why it is difficult to get rid of them. Continued accumulation of these plastics can be very harmful to the environment and human life in general. Hence, the need to get rid of them. And so far, recycling has proven to be the best method for this purpose.

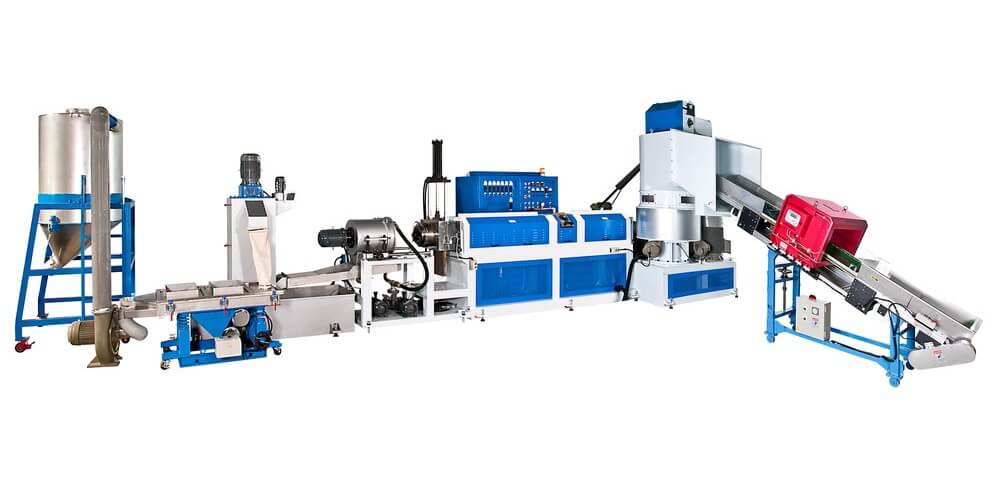

Brief Description of a Recycling Machine

A plastic recycling machine is mainly used for recycling Low-Density Polyethylene, Polyethylene film scrap, High-Density Polyethene, and Polypropylene.

The type of material used in the manufacture of these machines would depend greatly on force input, the sort of work it is expected to do, and other environmental factors. Also, the mechanical and physical properties of such components as well as their availability is equally considered.

Main components if a plastic recycling machine include;

- Frame

- Heating compartment

- The driveshaft

- Barrel

- The main housing

- Electric motor base

- Screw shaft

- The feed hopper

- Screw sprocket

- Chain sprocket

The primary function of the frame is to offer support and ensure that every moving component of the machine is properly aligned. The heating component is where the actual heating happens after which they are transferred to the barrel.

The electric motor & serves to power the machine and the hopper serve as a receiving end for the heated plastic. One rather interesting fact about the plastic recycling machine is that one can adjust the volume of the hopper unit, the heating chamber as well as the heating elements.

Benefits of plastic recycling machine

- The use of plastic recycling machines makes it possible for us to reuse waste plastic thereby minimizing the cost of production.

- Reduced cost of production invariably causes a reduction in the price of goods manufactured. Therefore, because of recycling, customers get to pay less.

- It helps us to get rid of excess plastic wastes that constitute a nuisance in the environment.

- Using this as a means of waste disposal helps to keep the environment free from pollution and protect arable lands for agricultural activities.

Plastic recycling machine: Areas that can be improved on

- Designing of an automatic feedback system to send back plastics that were not properly recycled the first time.

- Use of petrol or diesel in place of electricity as a means of generating power.

- Development of an efficient cleaning and sorting system.

- Addition of a cooling system to automatically cool the recycled plastic petals.

Conclusion

The Plastic recycling machine is indeed one great innovation as regards waste disposal. In addition to helping get rid of unwanted plastic and keeping the environment clean, it reduces the cost of production in plastic industries.