Different applications require gaskets for maintenance and operations. Most industrial and automotive equipment require gaskets. Also, they need routine replacements and upgrades. Some applications are unique and hence need custom-made gaskets. Fortunately, many manufacturers are providing these types of gaskets that meet the desired requirements. It is advisable to consider a company with many years of experience in making gaskets for various applications. You can find reputable companies making Reinforced PTFE Gasket & Sealing In China. These are some of the vital things you should consider when picking a custom gasket supplier.

Technical Knowledge

Nowadays, there are several gasket manufacturers. Before choosing a company, you need to ensure you understand their products well. Reliable suppliers do not push their products to customers to clear stock. Instead, they help you identify the right gasket that suits your needs and application.

Range of Materials

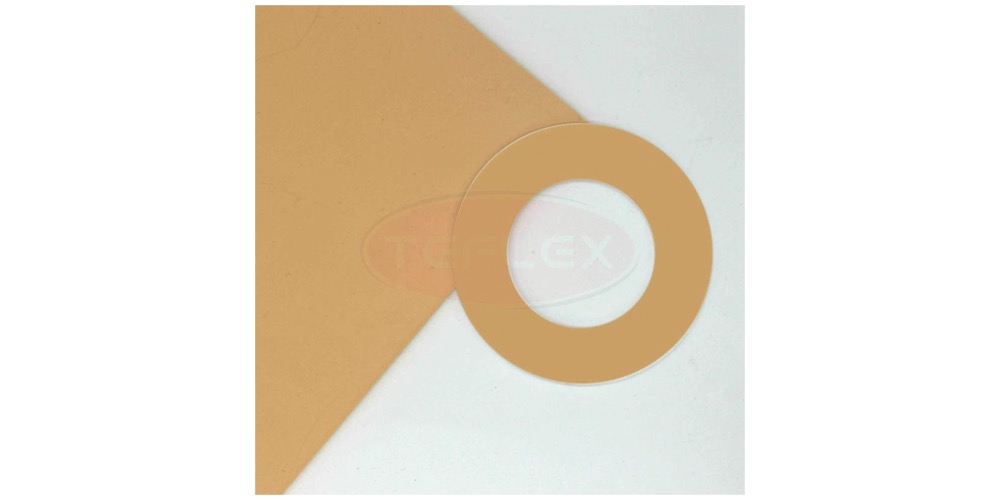

As you know, gaskets are made from a wide range of materials. Some of the materials used include rubber, metal, PTFE, and graphite. It is advisable to consider the conditions available before choosing a gasket. For instance, some applications are best suited for composite gaskets, whereas others require metallic gaskets. Ensure you choose a custom gasket manufacturer that offers you the ability to select appropriate materials.

Other than the range of materials used, you have to take into account their quality. Remember that gaskets are critical in various industrial and mechanical processes. Therefore, there is a need to investigate the reputation of the gasket manufacturer. Moreover, you ought to consider the quality control certifications awarded to the supplier.

Safety Features

The gasket supplier or manufacturer you select should have the capability to carry out the required tests. This is necessary to ensure the gaskets you purchase are safe and meet the industry standards. Some manufacturers even get their gaskets to be tested with independent laboratories before releasing them to the market.

Infrastructure

Since custom gaskets are meant for certain applications, you ought to choose a manufacturer that has the right tools and equipment. A top manufacturer can design and customize your gasket to have the features needed. Also, the manufacturer should use the latest technologies and have the best infrastructure.

Environmentally Friendly

Your custom gasket manufacturer should uphold the accepted ethics and regulations on environmental protection. For instance, you need to check whether the supplier uses eco-friendly materials. You should avoid companies that use asbestos to make gaskets as the material is a health risk.

Customer Support

When choosing a custom gasket manufacturer, you ought to take into account the level of customer service. Ideally, the supplier should have a well-trained and experienced support team to help you when it comes to installation and maintenance.

Pricing

Gaskets are used to prevent contamination and ensure safety. Thus, you should choose a custom gasket manufacturer that provides quality gaskets at a competitive price. Remember that cheaper gaskets are not always cost-effective. That is because they may not deliver the required performance. Also, you should find out whether the company has access to the gaskets. The company ought to have appropriate resources to ensure the processes run quickly and smoothly as possible.