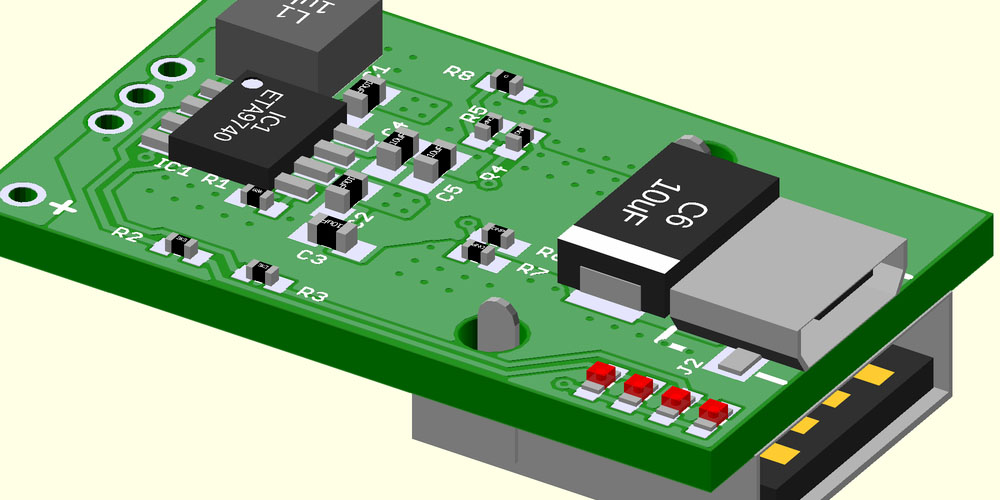

PCB designing is an important daily activity in the PCB industry. The purpose of a Printed Circuit Board is to create a physical form of an electronic circuit. Experienced electronic engineers are in charge of the development processes to form high-quality PCB designs. Multiple components are involved in a PCB product and are priced differently based on the manufacturer. Click here for a quote on the specific design you choose. Despite most PCB designs being lovely, few others come out with errors, and the quality is compromised; hence it’s vital to know which plan is the best. In this post, we highlight the guide for selecting a PCB design.

Guide for Selecting the Best PCB Design

The beauty of PCB designs is that you can design them from scratch or purchase one made already. Whichever route you take, for you to get a good quality PCB design, consider the following;

1. Layers of the PCB

Also known as stack-up, they vary in number depending on the design. It’s good to know how many layers you want before approaching the designer or seller. Also, suppose you decide to have the circuit board made from scratch. In that case, layer identification helps the engineer know the resistance of each layer electronically and the reliability and yield required for them to function as desired. In addition, the price of each item is determined, thus lowering the cost of production and the manufacturing process becomes easy and affordable

2. Materials of the Board

The board is one of the essential parts of the design. It forms the base for the PCB and supports all the electronic components mechanically. PCB is made of different materials, and selecting the right ones is vital. A combination of conductive and non-conductive materials plays a huge role in the functioning of the board.

Copper is a significant component used and allows current to flow in the circuit. Laminated glass material; FR4 from the glass-epoxy group forms the base. It has excellent mechanical strength, heat resistance ideal for current flow; that’s why manufacturers prefer it to other materials. FR4 material is affordable and readily avoidable; however, it cannot sustain high-performance circuits. PTFE material works best for such circuits to withstand any demanding activity through them. It is also cost-friendly and easily accessible to most users.

3. Selection of Parts

Part selection is a tedious step in the designing process that requires full attention. To get the best design, you must identify how many layers you need. The electronic engineer can guide you on the layer number, it can be single, double, or more, and they determine the product quality and whether or not errors will occur. It’s advisable to get readily available pieces for your board since they are widely used and sold in bulk.

4. Traces

Traces, mostly made of copper, are essential elements in the Printed Circuit Board design. They are good electrical conductors and have several benefits for the board.

Bottom Line

PCB design selection is necessary for any application. The tips provided above are straightforward, and both the customer and manufacturer can use them for high-quality and efficient design production. A good design minimizes errors and ensures the proper functioning of the circuit board.